NOVAX UV CHEF

Welded hoods with UV lamps

Simple capture - Air purification

NOVAX UV CHEF

New product

- Hood compliant with standard NF EN 16282-2

- Complete system ready to plug in

- High performance and long life UV lamps

- Triple safety device to avoid direct UV exposure

- Regulatory compliance with UV exposure

- Regulatory compliance with ozone concentration

- VIM commissioning

Application

Capture, filtration, purification - all types of kitchens.

Treatment of grease and odors.

Reduces the deposition of grease in the network on the exhaust fan.

Reduces the risk of fire.

Eliminates most of the odors upon discharge.

Variable flow rate possible with a minimum flow rate of 330 m³ / h / ml of hood.

-

Description

-

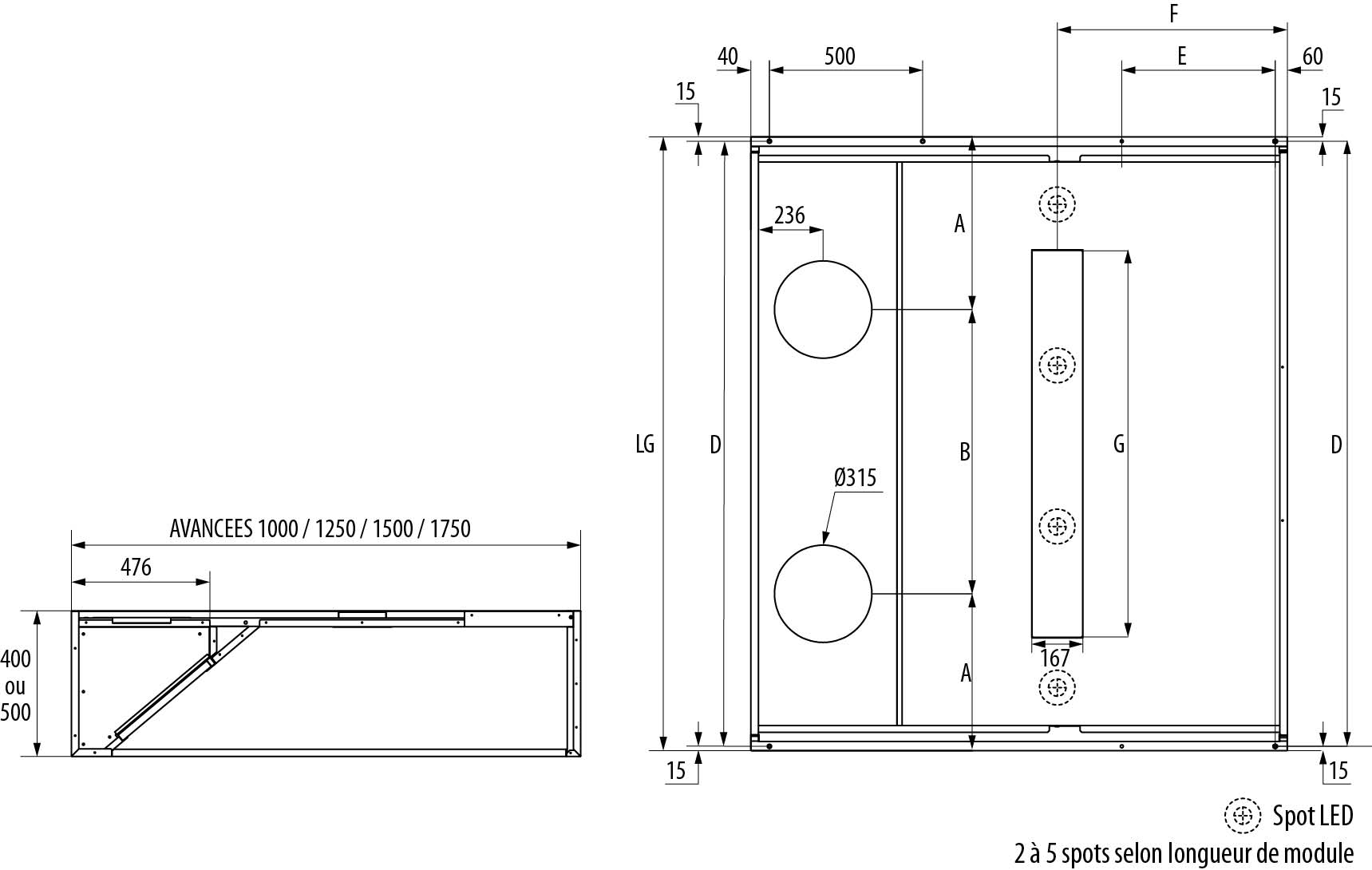

Dimensions

-

Documentation

-

Public Price

-

Software

-

References

Dimensions greater than 3000 mm made up of assembling modules without intermediate flange, ensuring visual and functional continuity.

Central hoods made by assembling back to back 2 hoods attached with partitions.

Module depth 1000, 1250, 1500 and 1750 mm.

Height 400 and 500 mm.

Reduced visor height available on request.

Each module integrates two UV lamps of length 900 mm (155W) or 1200 mm (250 W) and the safety devices.

ARUV control cabinets to manage up to 8 lamps.

Hood

- Hood made entirely of austenitic stainless steel AISI 304L (1.4307) with a 220 grain brushed finish.

- Constant height providing a large retention volume.

- Folded, welded and polished corners at the bottom, ensuring great rigidity and perfect sealing.

- Upper hood fixing system designed without any element passing through the extraction plenum in order to guarantee perfect sealing and cleanability.

- Lower peripheral gutters width 50 mm, height 25 mm with crushed folds and polished welded angles allowing the recovery of condensates for easy and safe cleaning.

- Lower face of the extraction sensor welded into the corners.

- 3/4" gas threaded drain purge and stainless steel cap. Crimped purge system, without roughness and without seal, guaranteeing constant cleanability and sealing over time.

- Lockable guillotine register integrated into each extraction tapping.

High efficiency specific shock filters

- All-stainless steel shock filters, flame arrester, compliant with NF EN 16282-6.

- Equipped with a covering profile to fill the space between two filters or a filter and a plate.

- Implementation of filters and design of the extraction plenum meeting regulatory limits for UV exposure (APAVE report).

Specific elements

- Disassembly of filters at a single location per module.

- Locking hatch with position contact.

- Safety pressure switch for authorizing the operation of the lamps.

- Connectors for lamps and security systems.

- Extensions with quick connectors for connecting one module to another.

- All the integrated technical elements relating to the UV systems are accessible from inside the hood.

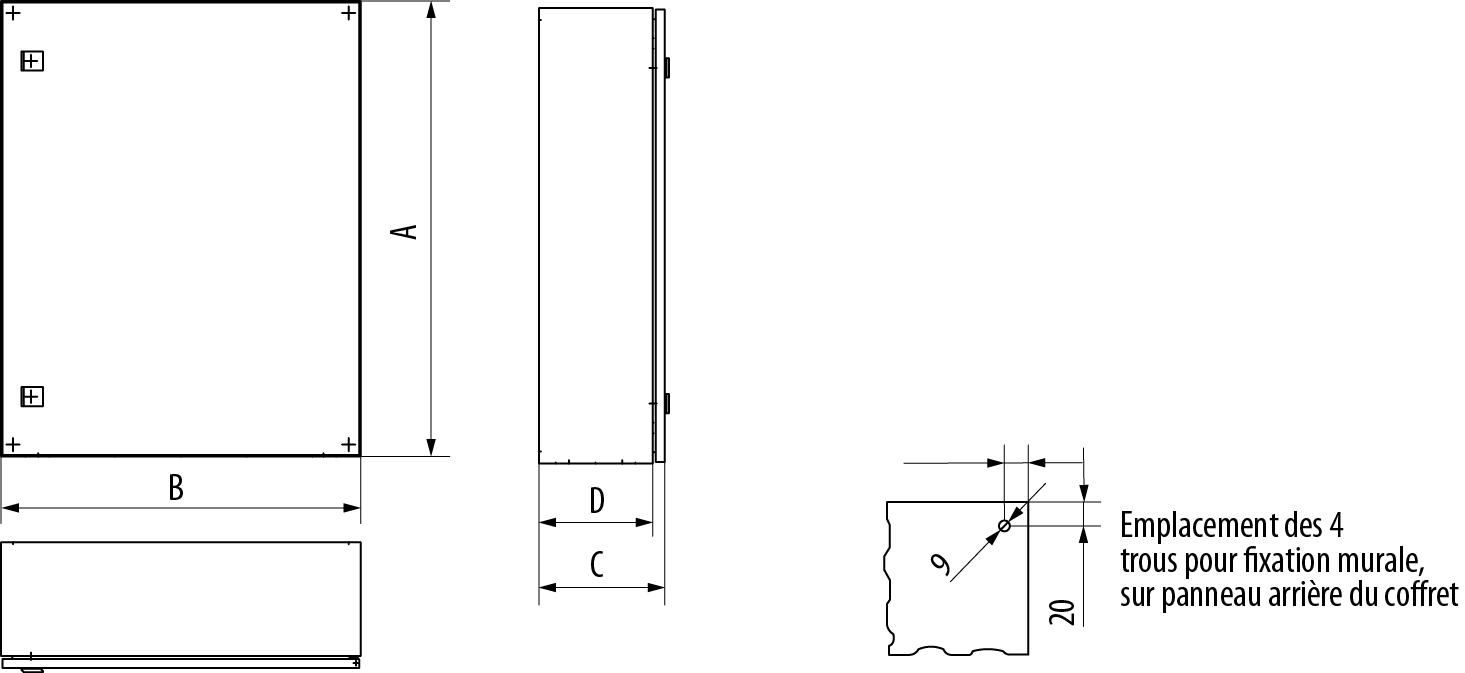

ARUV control and command cabinet

- In RAL 7035 steel, IP 54, Mono 230V power supply, 50/60 Hz

- Main switch.

- Lamp power button.

- Reset button.

- Indicator light on.

- Relay output for operating status.

- External control input.

- ARUV 2/4

- Connection of 2 or 4 lamps (1 or 2 modules).

- Power: 920 W - Dimensions: 400 x 600 x 150 mm.

- ARUV 6/8

- Connection of 6 to 8 lamps (3 to 4 modules).

- Power 1900 W - Dimensions: 600 x 760 x 210 mm.

UV lamps

- Length 900 mm - Power 155 W.

- Length 1200 mm - Power 250 W.

- Two lamps per module.

- Made of high purity synthetic quartz glass.

- High UV transmission between 185 and 254 nm.

- High performance, effective even at ambient temperatures up to 80°C.

- Long service life reaching 13,000 hours of service - reduction of 20% intensity at 185 nm then - minimizes maintenance frequency.

- 4 to 5 times more powerful than the market standard, a single lamp replaces a cassette containing 4 to 6 low pressure UV lamps.

OPTION

Recessed LED waterproof lighting with protective armoured glass, compliant with standard NF EN 16282-2.

- IP 55 - easy disassembly for tube replacement.

- 1 x 10 W lg 690 mm for 1000 mm module.

- 1 x 20 W lg 1300 mm for module from 1500 mm.

- 230 volts, 50 Hz, color 6000 K.

- Supplied with a 1.50 m connection cable.

- Fire resistance 90 minutes.

- IP 65.

- 230 volts, 50/60 Hz, dimmable, adjustable color (3000K, 4000K or 6000K).

- Dimensions: diameter 83 mm, height 86 mm. Possibility of unclipping the power supply unit to obtain a height of 53 mm and not to protrude from the hood.

- Spots mounted and wired on each module.

- Supplied with a 1.5 m connection cable.

FUNCTIONING

- The stale air drawn in by the hood passes through high-efficiency shock filters and then through 2 UV lamps placed across the tappings in the extraction sensor.

- Under the action of UV-C rays, the molecules are modified according to two combined effects, photolysis and ozonolysis, with the result of reducing grease deposits and neutralizing odors.

Photolysis effect

- UV radiation in the wavelength 185 nm and 254 nm breaks down long-chain molecules (fat molecules, etc.) by direct photolysis; the various chemical bonds are broken by the UV photons.

Ozonolysis effect

- UV photons react with oxygen in the air and create ozone (O3), which breaks down into active oxygen. Both compounds have a long-lasting oxidizing effect on molecules, removing grease and odors.

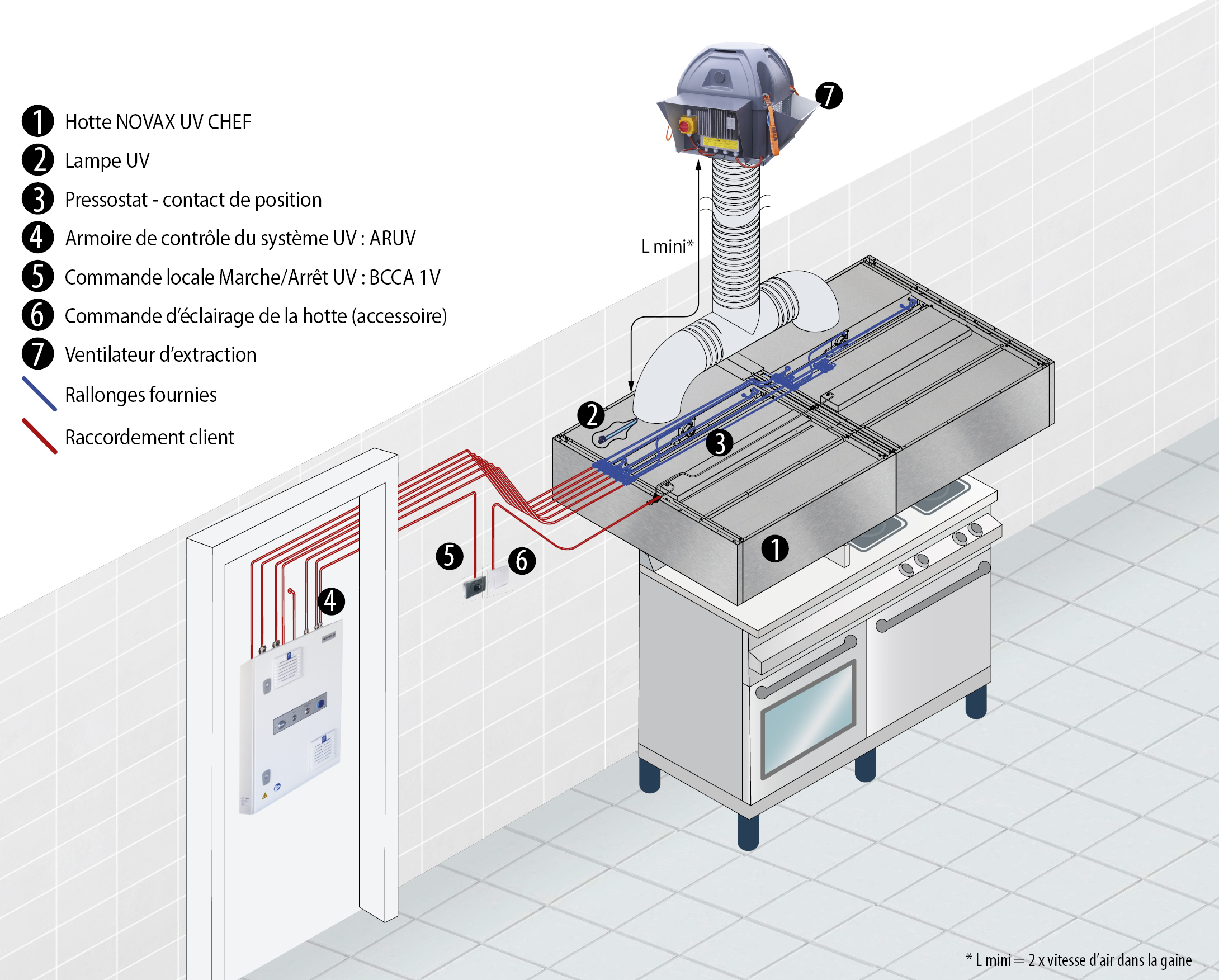

INSTALLATION SYNOPSIS

SAFETY DEVICES

- Triple safety device to prevent direct exposure to UV radiation of people present in the environment of the lamps:

- Position contact at the filters via a safety plate: when a filter is removed, operation of the lamps is not permitted.

- Use of specific impact filters compliant with NF EN 16282-6 equipped with a covering profile to fill the space between 2 filters and reduce radiation.

- Safety pressure switch inside the sensor of each hood: if the pressure (extraction flow) is insufficient, the operation of the lamps is not authorized. The safety pressure switch authorizes the switching on of the lamps above a pressure of 25 Pa (530 m3/h/ml of hood) in the extraction sensor and a cutting off of the lamps below 13 Pa (330 m3/h/ml).

INSTALLATION RECOMMENDATIONS

- Provide a waterproof network and ensure the waterproofing at the connection to the fan.

- Respect the regulatory distance of 8 meters between the stale air outlet and any fresh air inlet or opening.

- Discharge stale air into a free and naturally ventilated outdoor space/volume.

- Provide post-ventilation to avoid any possible unpleasant residual odor but not harmful to health.

- For better efficiency in the extraction network, the stale air must be in contact with the ozone for at least 2 seconds before discharge. If the speed in the duct is 3 m/s, the minimum length must be 6 m. L minimum duct [m] = 2 x V sheath [m/s].

- In the event that the implementation of sufficient duct length is not feasible or in the event that the residual odor of ozone at the discharge would be disturbing for the neighborhood, it is advisable to trap the ozone via a KPCA activated carbon box installed as close as possible to the stale air discharge.

COMPLIANCE WITH REGULATORY VALUES

VIM carried out measurements of UV exposure and ozone production in its laboratory.

UV exposure

- The measurements were carried out by APAVE.

The measured values are well below the regulatory limits and allow an exposure time of more than 8 hours. - Regulatory texts:

- Labor Code (articles R.4452-1 to R.4451-31)

- Decree 2010-750 of July 2, 2010 relating to the protection of workers against risks due to artificial optical radiation.

- Order of March 1, 2016 relating to the methods of assessing risks resulting from exposure to artificial optical radiation.

- Directive 2006/25/EC of 5 April 2016 relating to the minimum health and safety requirements regarding the exposure of workers to risks due to physical agents (artificial optical radiation).

Ozone production in the kitchen or at discharge

- The measurements were carried out by VIM .

- The measured values are well below the regulatory limits.

- Regulatory texts:

- Measures to prevent chemical risks (dangerous chemical agents): Articles R.4412-12 to R.4412-57 of the Labor Code. DRT Circular of the Ministry of Labor No. 12 of May 24, 2006 (not published in the Official Journal).

- Occupational exposure limit values (French): Circular from the Ministry of Labor dated July 19, 1982 (not published in the Official Journal).

Optional lighting - Supplied drilled with dampers fitted as standard

|

Module |

LG * |

Number of extraction holes |

A |

B |

D |

G |

Advanced 1000 |

Advanced 1250 |

Advanced 1500 |

Advanced 1750 |

||||

|

E |

F | E | F | E | F | E | F | |||||||

|

1500 |

1500 |

1 |

750 |

- |

1470 |

1265 |

- |

250 |

- |

500 |

500 |

625 |

500 |

750 |

|

2000 |

2000 |

2 |

512 |

976 |

1970 |

1265 |

- |

250 |

- |

500 |

500 |

625 |

500 |

750 |

|

2500 |

2500 |

2 |

643.5 |

1213 |

2470 |

1265 |

- |

250 |

- |

500 |

500 |

625 |

500 |

750 |

|

3000 |

3000 |

2 |

643.5 |

1713 |

2970 |

1265 |

- |

250 |

- |

500 |

500 |

625 |

500 |

750 |

* Total length of assembled modules: 3500, 4000, 4500, 5000, 5500, 6000

ARUV CABINET

|

Designation |

A |

B |

C |

D |

|

ARUV 2/4 |

600 |

400 |

150 |

129 |

|

ARUV 6/8 |

760 |

600 |

210 |

190 |

Detailed specifications

Detailed specifications

Text catalog pages (CT)

Installation instructions

Installation instructions

Installation instructions (NT)

Electrical / ATEX Certificates

Electrical / ATEX Certificates

Electrical CE Declarations (DCCE)

Prescription assistance

Prescription assistance

Specification text (TP)

Commercial documents

Commercial documents

Commercial leaflet (FCOM)

OPTAIR CUISINE must be completely re-installed.

For any operating problems, please send your request by email to optair@vim.fr

|

|