SYSTEME ASR2 ECOWATT

Manual or automatic

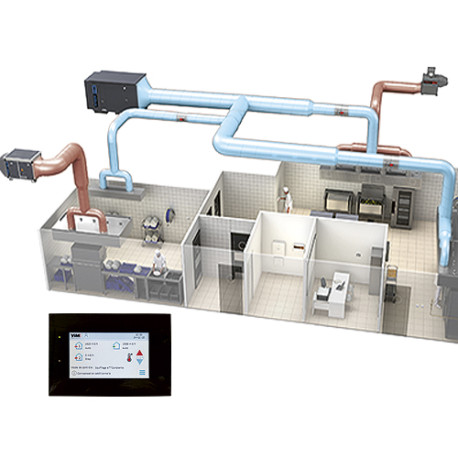

Multizone - Air extraction/introduction control

SYSTEME ASR2 ECOWATT

New product

| ErP compliant | ||||

- Complete kitchen air treatment management system

- Control of extraction and introduction flow rates

- Flow and temperature regulation

- Measurement and display of controlled parameters

- Security and alarm control

- Comfort management and smoke extraction

- VIM Commissioning

Applications:

Complete management of multi-zone ventilation and air treatment systems for all types of professional kitchens and laundries.

Combination of 1 to 3 extraction fans with a single AHU.

Application

Introduction of fresh air, filtration, heating and cooling.

Indoor or outdoor installation.

Treated air temperature -25 to +40°C.

-

Description

-

Dimensions

-

Documentation

-

Public Price

-

Software

-

References

- Control of one or more extraction fans with a single compensation unit.

- The distribution of fresh air in the different zones.

- Fire safety management.

- Comfort operation in manual, automatic or time-programmed mode.

- Control and monitoring of the operation of UVC treatment cabinets.

- Display and regulation of the different extraction and compensation flow rates.

- Centralization of operating and fault information from the air handling unit.

Comfort mode operation

- The two main extraction zones are equipped with a local CVF control which allows the simultaneous start-up of the associated extraction fan and the AHU and the opening of the corresponding VAV box. It also allows the extraction and compensation flow rates to be varied manually.

- For each zone, depending on the CVF setpoint, the CASR box will control the speed variation of the ECM motor of the corresponding ASR extraction fan and will transmit a flow setpoint to the VAV box.

- Flow control of the main extraction zones can be ensured by implementing a VORAX® ECO automatic management system.

- The BCCA 1V control of the fixed zone allows the simultaneous start-up of a standard extraction fan, the CTA and the opening of the VAV box.

- The three zones can be switched on independently.

- The system synthesizes the requested insufflation flow rates from the three zones and transmits a 0-10 volt signal to the CTA equipped with a CORRIGO VIM for flow control.

- The fresh air compensation flow rates can be supplied by hoods (VORAX® or NOVAX Confort 90/10 type compensation hoods) or by diffuser networks placed in the respective zones.

- As soon as the extraction fan in a zone is started, the CASR box will authorize the opening of the associated gas solenoid valve if it is present.

- In the case of an extraction zone containing a hood equipped with a grease and odor treatment system (NOVAX UV range), the CASR box will manage the start-up of the associated ARUV cabinet. By feedback on the operation of the UVC lamps, an operating hours counter will be incremented. A post-ventilation will allow the UV lamps to be stopped before the extraction fan in order to evacuate any ozone residues in the duct.

- The ETD2 RASR remote control displays the operating mode, real-time flow rates, and various system alarms, including the CTA alarm. It also allows the CTA's supply air temperature setpoint to be changed within the limit of an override of + or - 3 degrees.

Smoke evacuation mode

- Triggering a BDRA punch, regardless of the zone, activates smoke evacuation mode and activates the "fire" inputs of the CASR box, the CTA and the two fans of the variable zones. The "fire" inputs have priority over all other inputs regardless of the system's operating mode.

- In smoke evacuation mode, the extraction fans operate at their maximum speed, the gas solenoid valves are closed and the ARUV cabinets are stopped.

- Depending on the requirements of the safety commission, the CTA operates at its maximum flow rate or is stopped.

- A self-hold function is implemented and an alarm is generated on the ETD2 RASR remote control.

Detailed specifications

Detailed specifications

Text catalog pages (CT)

Public tariff price

Public tariff price

Price catalog pages (CP)

Commercial documents

Commercial documents

Commercial leaflet (FCOM)