SY STEM E ASR ECOWATT®

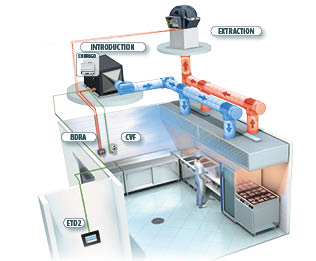

Single zone - Air extraction/introduction control

View larger

View larger

SY STEM E ASR ECOWATT®

New product

| ErP compliant | ||||

- Complete kitchen air treatment management system

- Control of extraction and compensation flow rates

- Flow and temperature regulation

- Measurement and display of controlled parameters

- Safety and alarm control

- Comfort and smoke extraction management

- VIM commissioning

Applications:

Parameterization, control, display and servo-control of air extraction and introduction flow rates in professional kitchens

Complete air handling system, combining an air handling unit with a compatible F400 exhaust fan

-

Description

-

Dimensions

-

Documentation

-

Public Price

-

Software

-

References

Management manual debits

Comfortable operation

- A unique local CVF control allows manual variation of extraction and introduction flow rates. It also stops the air handling unit and the exhaust fan.

- The KSDR ECOWATT type air handling unit® is equipped with a CORRIGO regulator which receives a 0-10V signal from the local CVF control to control the speed variation of its own ECM motor and that of the exhaust fan motor.

- The compensation flow can be blown in by the hood (VORAX type compensation hoods® COMFORT 90/10) or by a network of diffusers placed in the cooking zone or in the dining room.

- The blowing temperature is kept constant in winter thanks to a post-heating battery regulated and controlled by a motorized 3-way valve or by an electric heater. If the unit is equipped with a cold coil, the AHU will allow cooling in summer.

- The air handling unit's regulation can be connected to a BMS in Modbus or BACnet.

Smoke extraction operation

- If necessary, the BDRA punch can switch to smoke extraction mode by activating the "fire" input of the air handling unit and the extractor. This fire input has priority over all the other controller inputs such as the external start / stop input, but also if the unit has been shut down from the ETD remote control.

- The CORRIGO regulator forces the extractor to pass to its maximum speed, with a self-holding function. This function ensures the smoke extraction function, even if the punch is damaged by fire.

- All the regulating functions of the extractor are inhibited. A fire alarm is activated.

- According to the requirements of the safety commission, the compensation fan is managed according to 2 possibilities:

- Forcing the air handling unit fan to stop, closing the damper and closing the valve or cutting off the electric heater.

- Forcing the air handling unit fan to its maximum speed (water coil always regulated to protect it from freezing).

Adjustment and start-up

- The extraction fan and the AHU will have been selected at the maximum flow rate, with an extraction flow rate greater than the introduction flow rate, to keep the kitchen in slight depression.

- The exhaust fan flow display (TED ECOWATT® ASR, KUBAIR ECOWATT® ASR and JBRB ECOWATT® ASR) is possible thanks to a pressure transmitter connected to the pressure ports of the exhaust fan and to the CORRIGO regulator of the air handling unit.

- The ETD remote control of the air handling unit allows the adjustment of the minimum and maximum flow rates, the display of the flow rates (m3/ h) in real time and the change of temperature setpoint. It should be placed outside the area to be smoke free.

Security and alarms

- Checking the clogging of the fresh air filters by depressostat.

- Check the operation of the supply fan, the operation of the exhaust fan.

- Antifreeze safety on the hot water coil by contact probe.

- Overheating thermostat on electric heater.

- Post-ventilation to allow the battery to cool after shutdown.

- Motorized anti-freeze damper on the fresh air (option).

- Slaving of the gas valve to the operation of the extractor according to the decree of June 25, 1980.

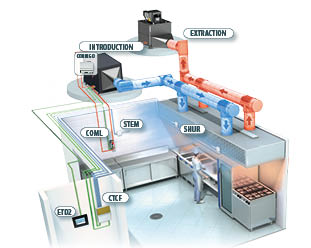

Management automatic debits

Comfortable operation

- Automatic flow management is carried out by the VORAX system® ECO thanks to relative humidity probes positioned on the front face of hoods and temperature probes placed in the kitchen. The flow rate varies linearly as a function of the temperature evolution as long as the humidity is below the set threshold. When the humidity exceeds the setpoint, the system gives it priority and goes to maximum speed.

- The KSDR ECOWATT type air handling unit® is equipped with a CORRIGO regulator which receives a 0-10V signal from the CTCF box for the speed variation of its own ECM motor and that of the exhaust fan motor.

- The compensation flow can be blown in by the hood (VORAX type compensation hoods® COMFORT 90/10) or by a network of diffusers placed in the cooking zone or in the dining room.

- The blowing temperature is kept constant in winter thanks to a post-heating battery regulated and controlled by a motorized 3-way valve or by an electric heater. If the unit is equipped with a cold coil, the AHU will allow cooling in summer.

- The air handling unit's regulation can be connected to a BMS in Modbus or BACnet.

Smoke extraction operation

- If necessary, the COML punch can switch to smoke extraction mode by activating the "fire" input of the air handling unit and the extractor. This fire input has priority over all the other controller inputs such as the external start / stop input, but also if the unit has been shut down from the ETD remote control.

- The CORRIGO regulator forces the extractor to pass to its maximum speed, with a self-holding function. This function ensures the smoke extraction function, even if the punch is damaged by fire.

- All the regulating functions of the extractor are inhibited. A fire alarm is activated.

- According to the requirements of the safety commission, the compensation fan is managed according to 2 possibilities:

- Forcing the air handling unit fan to stop, closing the damper and closing the valve or cutting off the electric heater.

- Forcing the air handling unit fan to its maximum speed (water coil always regulated to protect it from freezing).

Adjustment and start-up

- The extraction fan and the AHU will have been selected at the maximum flow rate, with an extraction flow rate greater than the introduction flow rate, to keep the kitchen in slight depression.

- The exhaust fan flow display (TED ECOWATT® ASR, KUBAIR ECOWATT® ASR and JBRB ECOWATT® ASR) is possible thanks to a pressure transmitter connected to the pressure ports of the exhaust fan and to the CORRIGO regulator of the air handling unit.

- The ETD remote control of the air handling unit allows the adjustment of the minimum and maximum flow rates, the display of the flow rates (m3/ h) in real time and the change of temperature setpoint. It should be placed outside the area to be smoke free.

- Checking the clogging of the fresh air filters by depressostat.

- Check the operation of the supply fan, the operation of the exhaust fan.

- Antifreeze safety on the hot water coil by contact probe.

- Overheating thermostat on electric heater.

- Post ventilation to allow the battery to cool after its shutdown.

- Motorized anti-freeze damper on the fresh air (option).

- Slaving of the gas valve to the operation of the extractor according to the decree of June 25, 1980.

Detailed specifications

Detailed specifications

Text catalog pages (CT)

Public tariff price

Public tariff price

Price catalog pages (CP)

Installation instructions

Installation instructions

Installation instructions (NT)

Installation instructions (NT) Other

Installation instructions (NT) Other languages

Prescription assistance

Prescription assistance

Commercial documents

Commercial documents

Commercial leaflet (FCOM)

CCAS LE BON ACCUEIL

CCAS LE BON ACCUEIL

Central kitchen / Food industry

79 - Deux-Sèvres

Installed products:

ECOLE HOTELIERE DE BIARRITZ

ECOLE HOTELIERE DE BIARRITZ

Specialized education

64 - Pyrénées-Atlantiques

Installed products:

HOTEL IMPERATOR

HOTEL IMPERATOR

Hotels

30 - Gard

Année : 2019

Maître d'ouvrage : PARIS INN GROUP

Installateur : SPIE INDUSTRIE ET TERTIAIRE VEDAS (dep. 34)

Architecte : CABINET COS

Installed products:

LE GRAND REFECTOIRE DE L'HOTEL DIEU

LE GRAND REFECTOIRE DE L'HOTEL DIEU

Independent commercial catering

69 - Rhône

Installed products:

LYCEE B. FRANKLIN - ORLEANS

LYCEE B. FRANKLIN - ORLEANS

High schools

45 - Loiret

Installed products:

LYCEE CHABRIER - YSSINGEAUX

LYCEE CHABRIER - YSSINGEAUX

High schools

43 - Haute-Loire

Installed products:

LYCEE HOTELIER SAVARY

LYCEE HOTELIER SAVARY

High schools

62 - Pas-de-Calais

Installed products:

LYCEE PROFESSIONNEL - AUBIN

LYCEE PROFESSIONNEL - AUBIN

High schools

Installed products:

MEDIATHEQUE L'AGORA - METZ

MEDIATHEQUE L'AGORA - METZ

Media library

57 - Moselle

Installed products:

PAUL BOCUSE

PAUL BOCUSE

Independent commercial catering

69 - Rhône

Installed products: