BATR R - BATR R010

Electric coils

Rectangular - Regulated

View larger

View larger

BATR R - BATR R010

New product

- ModBus communicating integrated regulation

- Integrated thermal protections

- Power from 6 to 66 kW

Application

Fits into a horizontal or vertical network of rectangular ducts.

Terminal heating or defrost.

Maximum outlet temperature 50 ° C.

-

Description

-

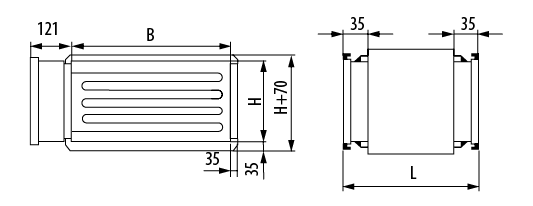

Dimensions

-

Documentation

-

Public Price

-

Software

-

References

Power from 6 to 66 kW.

Mono 230V 50Hz power supply, Tri 400V+N 50Hz.

BATR RC: autonomous.

BATR RC010: control by an external 0-10V signal.

BATR RC

Construction

- IP44 body and housing in aluzinc treated steel.

- Connection by undrilled flanges.

- IP44 cable gland to be cut

- Heating elements shielded in 304 stainless steel.

- TJK10K Duct Probe (IP20)

- Housing (IP20) equipped with an NTC10 room sensor and a setpoint adjustment potentiometer: 0 to 30°C.

Functioning

- Minimum speed = 1.5 m/s - Maximum speed = 10 m/s

- Two possible operating modes:

- Regulation of the blowing temperature in the duct.

- Room temperature regulation with low and high limitation of the blowing temperature (+15°C/+40°C).

Securities

- Air flow sensor for operation only when ventilation is present.

- Two safety thermostats:

- A 50°C automatic reset thermostat.

- A thermostat with manual reset 100°C.

- Power supply cut-off if one of the safety thermostats is triggered by an integrated contactor.

- Auxiliary relay with NO contact + NC contact, allows the battery overheating information to be transmitted to the CTA or GTC regulation.

- Plan to link the operation of the electric battery to the operation of the ventilation

- Provide post-ventilation to ensure cooling of the pins after ventilation is stopped (MCR1 accessory)

Regulation

- Triac type electronic power converter.

- 3 operating mode indicator lights: voltage/heating/fault presence.

- Digital input for remote operation authorization

- Modbus RTU communication on RS485 port.

BATR RC010

Construction

- IP44 body and housing in Aluzinc treated steel.

- Connection by undrilled flanges.

- IP44 cable gland to be cut.

- 304 stainless steel shielded heating elements.

Functioning

- Minimum speed = 1.5 m/s - Maximum speed = 10 m/s

- Heating power controlled by an external 0-10V signal from a single or double flow CTA with its own temperature regulation.

Securities

- Air flow sensor for operation only when ventilation is present.

- Two safety thermostats:

- A 50°C automatic reset thermostat.

- A thermostat with manual reset 100°C.

- Power supply cut-off if one of the safety thermostats is triggered by an integrated contactor.

- Auxiliary relay with NO contact + NC contact, allows the battery overheating information to be transmitted to the CTA or GTC regulation.

- Plan to link the operation of the electric battery to the operation of the ventilation

- Provide post-ventilation to ensure cooling of the pins after ventilation has stopped (CTA regulation).

Regulation

- Triac type electronic power converter.

- 3 operating mode indicator lights: voltage/heating/fault presence.

- Digital input for remote operation authorization

- Modbus RTU communication on RS485 port.

|

B (mm) |

H (mm) |

L (mm) |

Power (kW) |

|

400 |

200 |

370 |

6 to 12 |

|

400 |

200 |

420 |

15 |

|

500 |

250 |

370 |

6 to 12 |

|

500 |

250 |

600 |

24 |

|

500 |

300 |

370 |

9 to 24 |

|

500 |

300 |

440 |

30 |

|

600 |

300 |

370 |

9 to 18 |

|

600 |

300 |

440 |

27 |

|

600 |

300 |

520 |

36 |

|

600 |

350 |

370 |

12 to 30 |

|

600 |

350 |

520 |

42 |

|

700 |

400 |

370 |

15 to 42 |

|

700 |

400 |

440 |

60 |

|

800 |

500 |

370 |

21 to 39 |

|

800 |

500 |

500 |

66 |

|

1000 |

500 |

370 |

24 to 45 |

|

1000 |

500 |

370 |

66 |

Installation instructions

Installation instructions