CAD HR OPTIMAL

Double flow air handling unit V with exchanger

Counter flow - Backward - ECM < 8000 m3/h

CAD HR OPTIMAL

New product

|

ErP 2018 compliant - UVNR - Variable EC motors |

Filters

|

||||

Air-to-air plate heat exchanger produced by the RECUTECH company, which participates in the Eurovent program. Certification for AAHE. |

- Thermal efficiency up to 90%

- Modbus and BACnet communicating regulation

- High quality of finish

- Double skin rock wool insulation 50 mm

- Batteries integrated in the air handling unit

- High performance freewheel fans

- Low consumption ECM motors

- Recycling or mixing box

Applications:

Air introduction and extraction with energy recovery in tertiary premises.

Indoor or outdoor installation with roof.

Use in collective housing in addition to E15S type terminal valves on the extraction.

CAD / BIM

-

Description

-

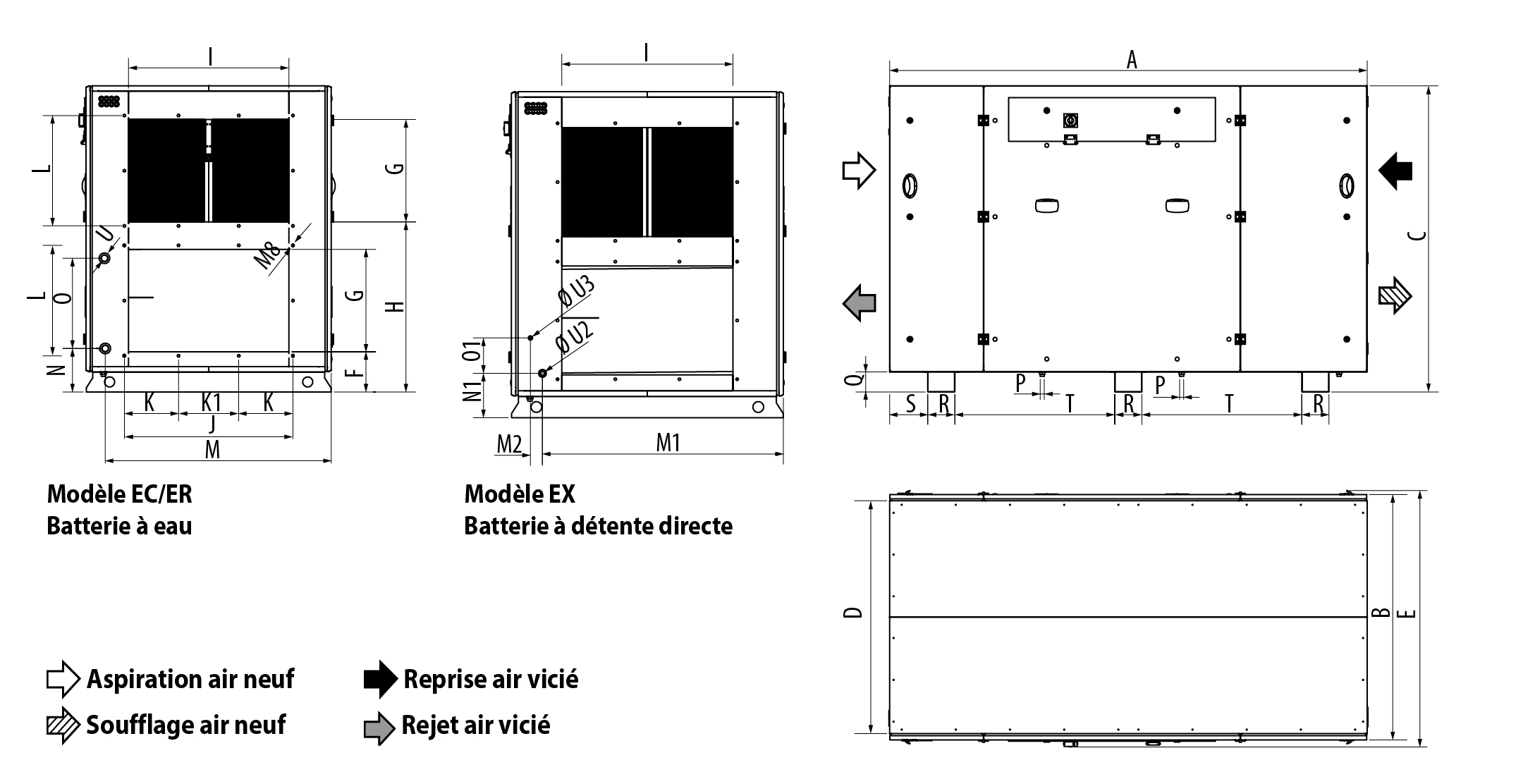

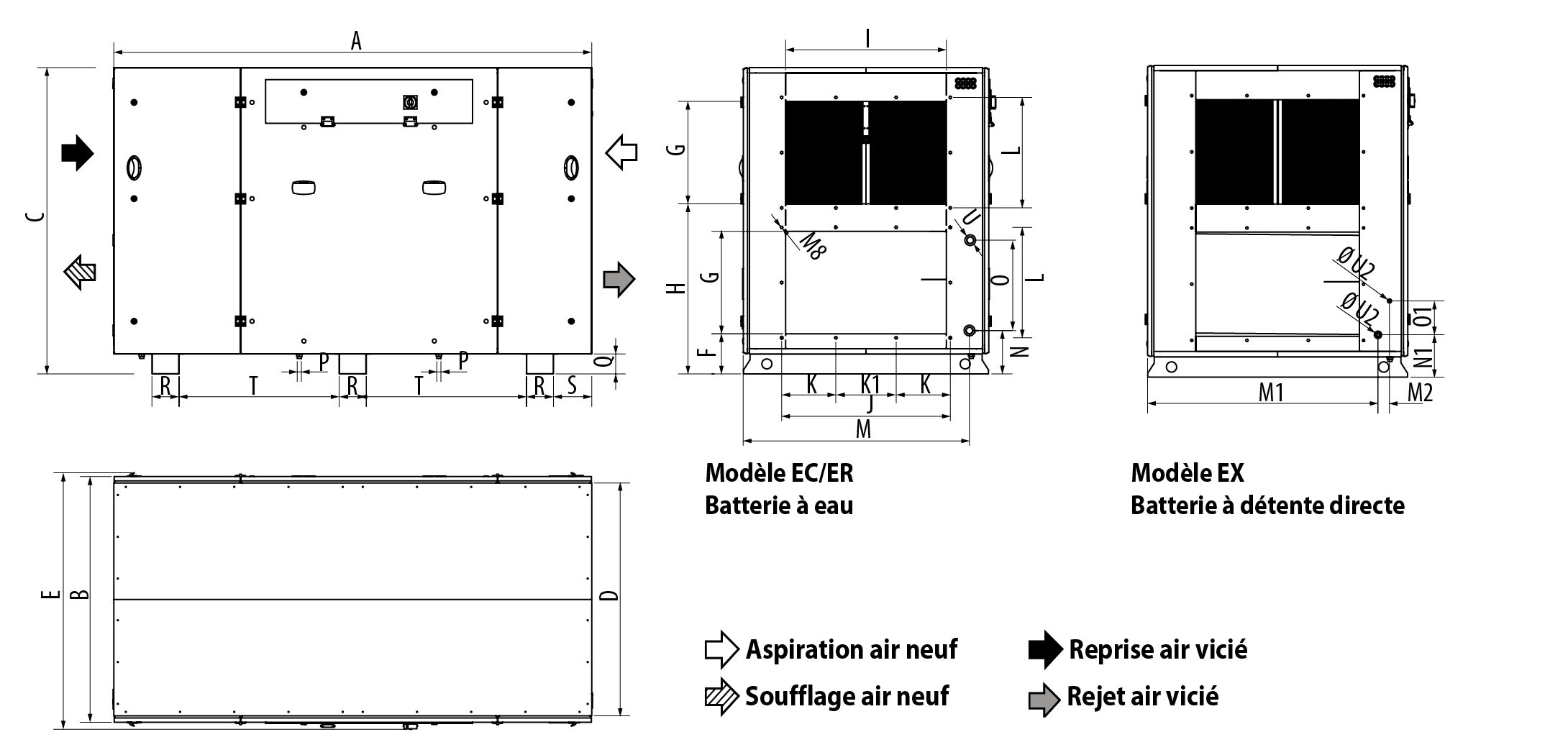

Dimensions

-

Documentation

-

Public Price

-

Software

-

References

From size 12 to 45, 10 models according to types of integrated batteries:

| BATTERY TYPE | |||||

| Electric post-heating | Post-heating hot water | Reversible water post-heating/cooling | Direct relaxation | Electric antifreeze exchanger | |

| E | |||||

| ED | ■ | ||||

| EI | ■ | ||||

| EDI | ■ | ■ | |||

| EC | ■ | ||||

| EDC | ■ | ■ | |||

| ER | ■ | ||||

| EDR | ■ | ■ | |||

| EX | ■ | ||||

| EDX | ■ | ■ | |||

- Sizes 56 and 80, 2 models: E = without battery, ED = with integrated defrosting battery. Post-heating batteries are only provided in the BAHR external battery box.

- BAHR External battery boxes. Optional for sizes 12 to 45, required for sizes 56 and 80.

- One-piece vertical (V) construction

- Duct connection configurations:

- VLD: online, right easement.

- VLG: online, left easement.

- VLEXD: in line with roof, right easement.

- VLEXG: in line with roof, left easement.

- 3 operating modes: variable flow (VAV), constant flow (CAV), constant pressure (COP).

- Integrated SCHNEIDER M172 regulation specific to VIM .

- Communicating Modbus RTU on RS485 or Modbus TCP/IP, BACnet IP or MSTP port. Remote touch control ETD M172 IP 20.

- Self-supporting construction in 50 mm double-skin panels.

- Insulation with 50 mm thick rock wool, density 40 kg/m³, thermal conductivity 0.037 W/(mk) (20/80°C) - A1 classification.

- Exterior finishes: pre-painted galvanized steel, dark gray RAL7024 color for environments of corrosion class C5, resistance to ultraviolet RUV5 according to EN 10169.

- Interior finishes in Z275 galvanized steel.

- Galvanized steel frame, height 100 mm up to size 45 and 155 mm for sizes 56 and 80. Drilling for fixing anti-vibration pads or leveling feet.

- Access doors to the main components on hinges and double seals. equipped with handles.

- Central access panel to the screwed exchanger equipped with double sealing gaskets and handles.

- Specific hinged hatch for access to the regulation.

- Connection by rectangular flange.

Classification

- Classification EN 1886 D2 / L2 / F9 / T2 / TB3 according to tests carried out by VIM .

Interchange

- High-efficiency air/air counter-current exchanger made of aluminum for an operating temperature of up to 80°C.

- Thermal efficiency up to 90%.

- Double stainless steel condensate recovery tank (on blowing and discharge) and 32 mm diameter siphons.

Bypass 100%

- Controlled by a proportional servomotor, used for free cooling and anti-freeze operation of the exchanger. By-pass damper blades equipped with gaskets to ensure maximum sealing (Class 4 according to EN1751).

Motorization

- Freewheel type reaction fans associated with an electronically commutated motor, ECM motors.

- Single-phase or three-phase motors with integrated electronic protection:

- CAD HR OPTIMAL 12/18/25: Mono 230V, 50/60Hz, IP54, class F, controlled by 0-10V signal.

- CAD HR OPTIMAL 33, 45/56/80: Tri 400 V, 50/60 Hz, IP54, class F, controlled by 0-10V signal.

Filtration

- Filters supplied as standard:

- Fresh air blowing: FIFI F7 ePM1 55 mini-pleat filters%.

- Stale air intake: FIFI M5 ePM10 50 pleated filters%.

- Optional filters available:

- Blowing fresh air:

FIGR G4 Coarse 70 pleated filter% + FIFI F7 ePM1 55 minifold filter%,

FIFI M5 ePM10 50 pleated filter% + FIFI F9 ePM1 80 minipleat filter%. - Stale air intake: FIFI F7 ePM1 55 mini-pleat filter%.

- Blowing fresh air:

Batteries integrated into the main unit or BAHR battery box:

EI/EDI electric battery

- Resistance in AISI 430 stainless steel.

- Safety thermostat with automatic reset, set point 55°C, manual reset 80°C.

- Proportional control by static relay.

- Sizes 25/33/45: separate battery power supply with its own proximity switch. In the case of an EDI model (with electric defrosting and post-heating battery), the power supply of the 2 batteries will be connected to the same proximity switch.

- 1 or 2 row water battery, for use in hot water.

- Frost protection by contact probe.

- Construction: copper tubes and collectors, threaded connection tubes, aluminum fins, galvanized steel frame.

- Motorized 3-way valve (24V) proportional by 0-1 0V signal (accessory).

- 4-row water battery, use in hot water or chilled water.

- Antifreeze protection by EDR/ER contact probe.

- Construction: copper tubes and collectors, threaded connection tubes, aluminum fins, galvanized steel frame.

- Motorized 3-way valve (24V) proportional by 0-10V signal (accessory).

- Stainless steel condensate recovery tray and siphon for Ø32 connection.

- Equipped with a droplet separator.

- THCO “change over” probe allowing automatic Hot/Cold switching by measuring the water temperature on ER and EDR.

- 2 or 3 row battery designed to operate in evaporation or condensation.

- Construction: copper tubes and collectors, aluminum fins, galvanized steel frame.

- Stainless steel condensate recovery tray and siphon for Ø32 connection.

- Equipped with a droplet separator.

- The regulation of the direct expansion battery must be carried out by the DX group.

- Resistance in AISI 430 stainless steel.

- Safety thermostat with automatic reset, set point 55°C, manual reset 80°C.

- Proportional control by static relay.

- Sizes 25/33/45/56 and 80: power supply of the defrost battery by separate power supply with its own proximity switch. In the case of an EDI model (with electric post-heating battery), the power supply of the 2 batteries will be connected to the same proximity switch.

- BAHR EI : post-heating electric battery.

- BAHR EC1R or EC2R : hot water battery.

- BAHR ER : reversible hot/cold water battery.

- BAHR EX : direct expansion battery.

- BAHR ECF : hot water battery and cold water battery.

- BAHR EIF on size 56 and 80:

- 1 electric battery

- 1 4-row cold water battery

- BAHR EIX on size 56 and 80:

- 1 electric battery

- 1 DX 3-row battery

- Self-supporting construction in 50 mm double-skin panels.

- Mineral wool insulation, 50 mm thick, density 40 kg/m³, thermal conductivity 0.037 W/(mk) (20/80°C) - A1 classification.

- Exterior finishes: pre-painted galvanized steel, dark gray color RAL7024. Corrosion resistance C5, ultraviolet resistance RUV3 according to EN 10169.

- Interior finishes in Z275 galvanized steel.

- Galvanized steel frame, height 100 mm, drilling for fixing anti-vibration pads or leveling feet.

CMHR recycling or mixing box

- Attaches directly to the VL model CTAs.

- Self-supporting construction in double-skin panel.

- Mineral wool insulation, thermal conductivity 0.037W (mk).

- Exterior finish: pre-painted galvanized steel, dark gray color RAL7024, corrosion resistance C5 and ultraviolet resistance RUV3 according to EN 10169.

- Interior finish in Z275 galvanized steel.

- Access to components on the main face via doors.

- Connection, by rectangular flange.

- 3 rectangular registers.

- Proportional register motors or proportional motor with safety function (return spring).

- 2 selectable regulation modes:

- All-or-nothing recycling management on time programming. Possibility of setting minimum or maximum stops for opening or closing the shutter to maintain a minimum of fresh air for example.

- Management of the fresh air/recycled air mixture according to the indoor air quality (CO2). Proportional operation, promotes air recirculation during periods of non-occupation, and all-fresh air operation when the premises are occupied. CO2 probe (accessory) to be connected to the control.

Rectangular accessories

- CDRE 100 : motorized rectangular register, reinforced class 3 sealing, class B casing.

- MSCE : waterproof rectangular flexible cuff (class B) with frame, M0.

- APPA - APPR : rain canopy for suction or discharge. Made of galvanized steel, pre-painted RAL7024, of the same type as the unit. Trapdoor on the side for access to a possible damper servomotor. Quick fixing without drilling.

- BRL : smooth rectangular flange made of galvanized steel.

- PRRE : rectangular/round transformation piece in galvanized steel up to size 45.

- PRCN/PRCI - Adapter plate for circular connection, bare or insulated, from size 12 to 45.

- PRCN - galvanized steel plate equipped with a joint tapping (supplied with sealing gasket).

- PRCI - 50mm double skin panel, rock wool insulation, finish identical to the unit, circular tapping with joint (supplied with sealing gasket and long fixing screw).

- Also suitable for BAHR battery boxes from size 12 to 45.

Air treatment selection

Connection to straight servitude line

CAD HR OPTIMAL VLG

Left servitude line connection

|

CAD HR OPTIMAL size |

A |

B |

C |

D |

E |

F |

G |

H |

I |

I |

K |

K1 |

L |

M |

M1 |

|

12 |

1976 |

715 |

1151 |

655 |

754 |

209 |

310 |

669 |

400 |

440 |

220 |

- |

350 |

627 |

625 |

|

18 |

1976 |

842 |

1151 |

785 |

881 |

209 |

310 |

669 |

500 |

540 |

270 |

- |

350 |

757 |

740 |

|

25 |

2355 |

1171 |

1382 |

1109 |

1209 |

200 |

410 |

775 |

800 |

840 |

270 |

300 |

450 |

1071 |

1047 |

|

33 |

2355 |

1171 |

1382 |

1109 |

1209 |

200 |

410 |

775 |

800 |

840 |

270 |

300 |

450 |

1071 |

1047 |

|

45 |

2380 |

1273 |

1525 |

1210 |

1310 |

200 |

510 |

847 |

800 |

840 |

270 |

300 |

550 |

1180 |

1125 |

|

56 |

2380 |

1788 |

1685 |

1731 |

1827 |

280 |

510 |

955 |

1300 |

1340 |

220 |

300 |

550 |

- |

- |

|

80 |

2380 |

2280 |

1785 |

2223 |

2319 |

255 |

610 |

1005 |

1700 |

1740 |

270 |

300 |

650 |

- |

- |

|

CAD HR OPTIMAL size |

M2 |

N | N1 | O | O1 | PØ | Q | R | S | T | ØU2 | ØU3 | U (EC) | U (ER) | Weight without any Battery E (kg) |

|

12 |

10 |

205 | 206 | 307 | 117 | 1/2" | 100 | 135 | 231 | 555 | 22 | 12 | 3/4" | 3/4" | 348 |

|

18 |

20 |

205 | 206 | 307 | 117 | 1/2" | 100 | 135 | 231 | 555 | 22 | 12 | 3/4" | 3/4" | 388 |

|

25 |

40 |

213 | 208 | 390 | 144 | 1/2" | 100 | 135 | 245 | 730 | 28 | 16 | 3/4" | 3/4" | 506 |

|

33 |

40 |

213 | 208 | 390 | 144 | 1/2" | 100 | 135 | 245 | 730 | 28 | 16 | 3/4" | 1" | 617 |

|

45 |

55 |

214 | 208 | 457 | 166 | 1/2" | 100 | 135 | 210 | 777 | 28 | 22 | 3/4" | 3/4" | 699 |

|

56 |

- |

- | - | - | - | 1/2" | 155 | 196 | 180 | 716 | - | - | - | - | 915 |

|

80 |

- |

- |

- | - | - | 1/2" | 155 | 196 | 180 | 716 | - | - | - | - |

1123

|

Detailed specifications

Detailed specifications

Text catalog pages (CT)

Catalog Pages - Other

Public tariff price

Public tariff price

Price catalog pages (CP)

Installation instructions

Installation instructions

Installation instructions (NT)

Installation instructions (NT) Other

Installation instructions (NT) Other languages

Technical data (DTEC)

Fire / Smoke extraction certificates

Fire / Smoke extraction certificates

Fire classification report (PVFEU)

Performance / Environment Certificates

Performance / Environment Certificates

ErP regulatory sheet (FERP)

Eurovent certificate (CEUR)

Declaration of performance (DOP)

Product environmental profile (PEP)

Electrical / ATEX Certificates

Electrical / ATEX Certificates

Electrical CE Declarations (DCCE)

Prescription assistance

Prescription assistance

Specification text (TP)

Other files

Other files

Other files

Commercial documents

Commercial documents

Commercial leaflet (FCOM)

LYCEE HOTELIER SAVARY

LYCEE HOTELIER SAVARY

High schools

62 - Pas-de-Calais

Installed products:

Order online

Order online