CAD HR SLIM

Double flow air handling unit H with exchanger

Counter-current - Ceiling - ECM < 2500 m3h

View larger

View larger

CAD HR SLIM

New product

| ErP 2018 compliant - UVNR - Variable EC motor |

Filters

|

||||

Air-to-air plate heat exchangers produced by the company ERI, which participates in the Eurovent Certification program for AAHEs. |

- Double skin rock wool insulation 30 mm

- By-pass 100% proportional for free-cooling and defrost

- Low consumption ECM motor

- Access from below by sliding door

- Access to filters from below or from the side

- Integrated condensate drain pump

- Integration of a defrost coil on site

Applications:

Air introduction and extraction with energy recovery in tertiary premises.

Particularly suitable for false ceiling installation in renovation as in new.

Indoor use only.

-

Description

-

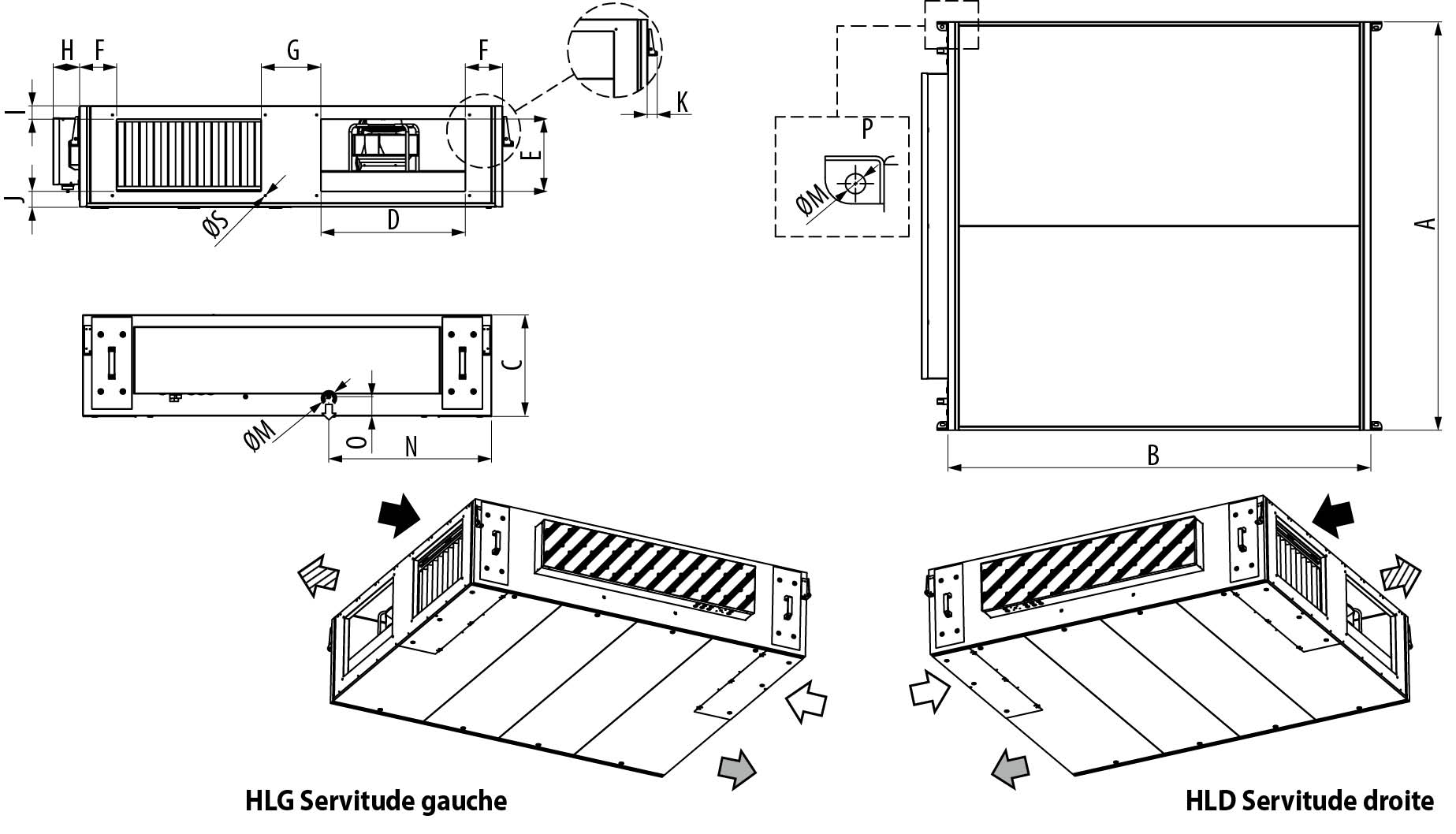

Dimensions

-

Documentation

-

Public Price

-

Software

-

References

2 models:

- E: without defrost battery

- ED: with integrated defrosting battery

- EI: Post-heating electric battery

- EC: Hot water battery

- ER: Reversible water battery

- EF: Cold water battery

- EX: Direct expansion battery

- HLD: In line right servitude, blowing to the right of the control box

- HLG: In line left servitude, blowing to the left of the control box

Modbus RTU on RS485 port, Modbus TCP/IP, BACnet IP, BACnet MSTP,

Three operating modes: variable flow (VAV), constant flow (CAV), constant pressure (COP).

ETD2 remote touch control.

Construction

- Self-supporting galvanized steel structure box.

- Panels double skin thickness 30 mm with rock wool insulation (Euroclass A1), 100kg/m3, thermal conductivity 0.037W/(mk).

- Exterior/interior finish in Z275 galvanized steel.

- Access from below for all components thanks to sliding doors, easy maintenance.

Interchange

- High-efficiency air/air counter-current exchanger, made of aluminum for an operating temperature of 80°C.

- Thermal efficiency up to 94%.

- Recovery tank equipped with a factory-connected condensate lifting pump.

Bypass 100%

- Placed on the fresh air, controlled by a proportional servomotor, used for free cooling and the anti-freeze strategy of the exchanger.

Motorization

- Metallic freewheel type reaction fan (incombustible A1) associated with an ECM electronically commutated motor.

- Single-phase or three-phase motors with integrated electronic protection: Mono 230 V, 50/60 Hz, IP54, Control by 0-10V signal.

Filtration

- Filters supplied as standard

- FIFI F7 ePM1 70 fresh air blowing%.

- FIFI M5 ePM10 50 stale air recovery%.

- Filters available as an option

- Fresh air blowing FIFI F9 ePM1 80%.

- Access to filters from below or from the side.

Regulation

| FLOW RATE ADJUSTMENT | RECOMMENDED APPLICATIONS |

| VAV MODE - VARIABLE FLOW | |

| Fan speed variation by 0-10 V signal | |

| - Flow rate setpoint value based on a 0-10 V signal from an external probe (CO2, temperature, humidity, etc.). | - Single-zone installations, requiring ventilation adaptation depending on occupancy |

| CA MODE - CONSTANT FLOW | |

| Fan speeds set to a specific flow rate | |

| - 3 maximum constant flow rate settings, entry of values with reading on display. - Switching between the different instructions carried out manually from the remote control or automatically by clock or presence detection. |

- Installations requiring control of one or more specific flow rates. |

| COP MODE - CONSTANT PRESSURE | |

| Automatic fan speed variation to maintain constant pressure | |

| - Flow rate automatically modulated to maintain a constant pressure value measured by an external probe (pressure probe accessory). | - Multi-zone ventilation installations, associated with modulation of terminal flow rates. |

Built-in antifreeze electric battery (ED model)

- Delivered fully pre-wired and connected to the regulator.

- Includes: static relay for modulation of heating power, temperature probe, thermal protection with automatic reset (60°C) and manual reset (85°C).

BASL - External modules for batteries

Construction

- Self-supporting galvanized steel structure box.

- Double skin panels, 30 mm thick, with rock wool insulation (Euroclass A1), 100 kg/m3, thermal conductivity 0.037W/(mk).

- Exterior/interior finish in galvanized steel.

- AISI321 stainless steel pin and aluzinc fins.

- Overheating thermostat, automatic reset 60°C, manual reset 85°C.

- Integrated blowing temperature sensor to be connected to the main unit.

- Power connection to the disconnect switch.

- 2-row hot water battery, copper tube and aluminum fins.

- Antifreeze protection probe on the water return.

- Integrated blowing temperature probe.

- 3-way motorized valve proportional by 0-10V signal (accessory).

- 3-row water battery, copper tube and aluminum fins.

- Antifreeze protection probe on the water return.

- “Change over” thermostat allowing automatic hot/cold switching by measuring the water temperature.

- Welded condensate collection tray, made of galvanized steel with 01/2" drain.

- 24V 3-way valve motorized proportional by 0-10V signal (accessory).

- Integrated blowing temperature probe.

- 5-row water battery, copper tube and aluminum fins.

- Welded condensate collection tray, made of galvanized steel with 1/2" drain.

- 24V motorized 3-way valve proportional by 0-10V signal (accessory).

- Integrated blowing temperature probe.

- 4-row battery, copper tube and aluminum fins.

- Reversible evaporation/condensation operation.

- Welded condensate collection tray, made of galvanized steel with 01/2" drain.

- Integrated blowing temperature probe.

- The regulation of the direct expansion battery must be carried out by a DX group.

Air treatment selection

| Fresh air suction | |

| Blowing fresh air | |

| Stale air recovery | |

| Stale air rejection |

| Size | A | B | C | D | E | F | G | H | I | J | K | M | N | O | Weight (kg) |

| SLIM 08 | 1700 | 1080 | 380 | 400 | 200 | 85 | 110 | 110 | 55 | 125 | 45 | 8 | 685 | 80 | 172 |

| SLIM 12 | 1700 | 1560 | 380 | 500 | 250 | 155 | 250 | 110 | 55 | 75 | 45 | 8 | 685 | 80 | 231 |

| SLIM 16 | 1700 | 1760 | 420 | 600 | 300 | 155 | 250 | 110 | 55 | 65 | 45 | 8 | 677 | 80 | 266 |

| SLIM 20 / 24 | 2000 | 1760 | 500 | 600 | 350 | 155 | 250 | 110 | 55 | 95 | 45 | 8 | 785 | 86 | 315 |

Detailed specifications

Detailed specifications

Text catalog pages (CT)

Catalog Pages - Other

Public tariff price

Public tariff price

Price catalog pages (CP)

Installation instructions

Installation instructions

Installation instructions (NT)

Fire / Smoke extraction certificates

Fire / Smoke extraction certificates

Fire classification report (PVFEU)

Performance / Environment Certificates

Performance / Environment Certificates

Eurovent certificate (CEUR)

Electrical / ATEX Certificates

Electrical / ATEX Certificates

Electrical CE Declarations (DCCE)

Prescription assistance

Prescription assistance

Specification text (TP)

Commercial documents

Commercial documents

Commercial leaflet (FCOM)

|

Products included in version 2023

|

Order online

Order online