THGT HATCH F400

Axial fans F400 or F200

Tubular - AC < 130,000 m3/h

View larger

View larger

THGT HATCH F400

New product

| ErP 2015 compliant Fan |

||

- Axial exhaust fan mounted in a box

- Limits energy loss

- Motorized cover, withstands severe weather conditions

- Certified F400-120 in an environment of 400°C, gas and fan

Application

Extraction of fumes and hot gases in case of fire.

Extraction of stale air from tertiary and industrial premises.

Installation for vertical extraction.

-

Description

-

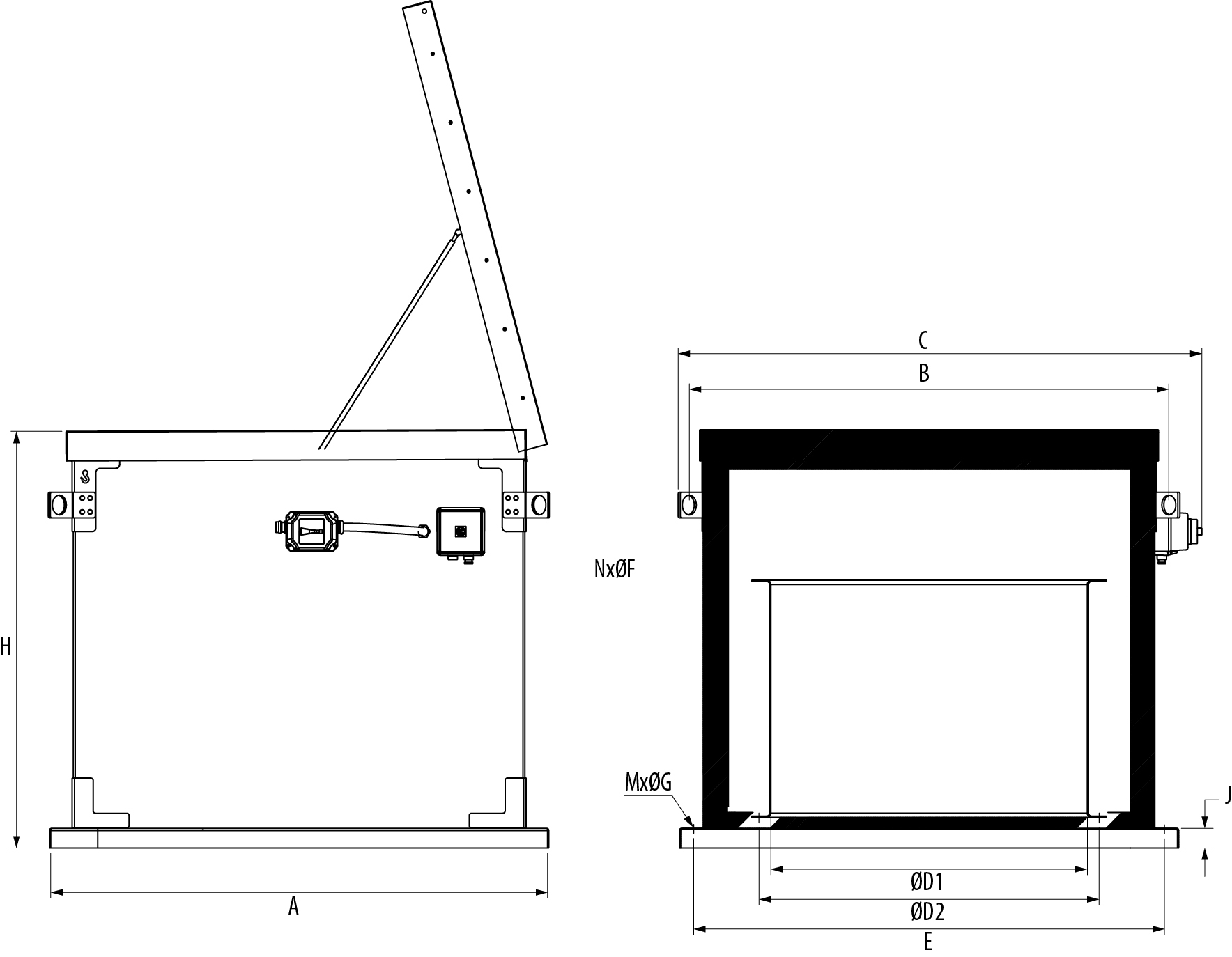

Dimensions

-

Documentation

-

Public Price

-

Software

-

References

Approved F400 120 and F200 120.

9 sizes: Ø 500 / 560 / 630 / 710 / 800 / 900 / 1000 / 1120 / 1250 mm.

Air direction A (motor/fan).

ErP data available in Easyvent.

Construction

- Box incorporating a long shell made of hot-dip galvanized steel sheet in accordance with EN 1461. Double-skin panels with 50mm polyurethane insulation.

- Box and ferrule for corrosion class C4 environments.

- High-efficiency propeller in die-cast aluminium, dynamically balanced according to ISO 14694: G6.3. 3, 5, 6, 7, 9 or 12 blades with variable pitch angles when stationary except with 2-pole motor, to respond precisely to all flow/pressure requirements. Certified THGT fan AMCA.

- The standard design incorporates a base.

- Waterproofing

- Insulation U = 0.42W/(m2K) without thermal bridge.

- Snow load SL 1000 at -25°C according to EN 12101-2.

- Wind load WL 1000 (size 4) or 1500 (sizes 1 to 3) according to EN 12101-2.

- 20,000 cycle opening mechanism with opening/closing limit switches for external control.

- Connection boxes IP65 independent for motor with disconnector and for servomotors (220-240V 50Hz IP65).

Motorization

- Three-phase asynchronous motor directly coupled to the propeller, without thermal protection, Services S1 and S2. 1-speed motors by default

- Suitable for corrosion class C3 environments.

- Possible control by frequency variation.

- 1-speed motor with B3 feet, IP55, class H:

- three-phase 2, 4 or 6 poles 230/400V, 50/60Hz* up to 3 kW.

- three-phase 2, 4 or 6 poles 400V, 50Hz above 3 kW.

- 2-speed motor (Dahlander windings) with B3 legs, IP55, class H:

- three-phase 2/4, 4/8 or 6/12 poles 400V, 50Hz.

- * According to characteristics

- The engine should start within a minimum of 20 to 36 seconds after the lid is opened, depending on product specifications.

| Cut | Model | Dimensions (mm) | |||||||||||

| HAS | H | B | VS | ØD1 | ØD2 | E | NOT | F | M | G | J | ||

| 1 | 500 | 1076 | 1058 | 1032 | 1143 | 500 | 560 | 1009 | 12 | 12 | 4 | 14 | 50 |

| 560 | 560 | 620 | |||||||||||

| 630 | 630 | 620 | |||||||||||

| 2 | 710 | 1256 | 1058 | 1212 | 1325 | 710 | 770 | 1190 | 16 | 12 | |||

| 800 | 800 | 860 | |||||||||||

| 3 | 900 | 1455 | 1164 | 1412 | 1550 | 900 | 970 | 1390 | 16 | 15 | |||

| 1000 | 1000 | 1070 | |||||||||||

| 4 | 1120 | 1704 | 1394 | 1662 | 1815 | 1120 | 1190 | 1640 | 20 | 15 | |||

| 1250 | 1250 | 1320 | |||||||||||

Detailed specifications

Detailed specifications

Text catalog pages (CT)

Installation instructions

Installation instructions

Installation instructions (NT)

Fire / Smoke extraction certificates

Fire / Smoke extraction certificates

CE smoke extraction certification (CCCE)

Commercial documents

Commercial documents

Commercial leaflet (FCOM)